Minting in ancient times

By their very nature, coins are highly durable, convenient, mobile and accurate modes of payment

and investments. In order to meet these specifications, minting techniques have traditionally been highly precise

and guarded functions commissioned and governed by a country's reigning authorities and a few hand selected mints

in the world. From the outset, minting techniques consisted of two main areas of work - the production of suitable

blanks of a defined composition and exact weight; and the production of the tools for striking the coins.

Principally, nothing has changed in this regard from the earliest minting techniques till today.

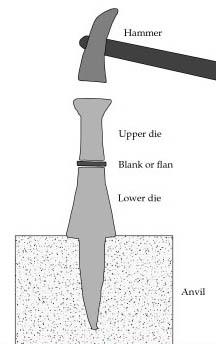

Only the methods have improved with industrialisation and technical progress. Even from the earliest times, coins

were struck with 2 coining dies - a lower die depicting the coin in a negative form, and a similar upper die. The

coin blank was then placed between these two dies and the upper die struck with a heavy hammer, thus rendering a

positive image on the blank. The hammer method was used a long way into the Middle Ages. Even now we occasionally

speak of coins being struck.

A historical approach

It is believed that the first coins were struck during the 7th century BC by the

Lydians in Asia Minor. These were made from coin blanks of a consistent

composition of gold/silver alloy called electrum. For this purpose, molten electrum was poured into suitable

forms. Although they started with simple moulds, later on there was a transition to more complicated ones which

made the production of a larger number at any one time possible. For many centuries, this kind of production of

round coin blanks remained basically unaltered until the growing economy in Europe during the 16th century saw a

dramatic increase in demand for coins. Minting techniques therefore were industrialised to meet this demand.

Coining by hammer

During the XVI century, a hammer was used to reduce the thickness of a sheet of metal, in which

the blanks are cut out by shears, then filed and hammered to reach the desired weight and thickness. As it is

depicted in the stained-glass window showing a coin workshop in Strasbourg, the coin maker carries out the so-called

striking according to the following process:

- The workman puts the blank on the fixed die

- The mobile die is held above by hand

- The workman strikes several blows with a hammer

Coining by screw press (since about 1550)

The early modern period witnessed probably the most dramatic change in methods of coin

production. Around 1550, the German silversmith Marx Schwab invented coining with the screw press. The novelty was

that two heavy iron screws pressed the coin metal to the desired thickness. The preparation of blanks was aided by

roller-mills with produced uniformly thick strips from which the blanks could be cut with metal punches. Henri II

(1547-1559) imported the new machines: rolling mill, punch and screw press. 8 to 12 men took over from each other

every quarter of an hour to manoeuvre the arms driving the screw which struck the medals. Henri II came up against

hostility on the part of the coin makers, so the process was only to be used for coins of small value, medals and

tokens. In 1645 it came into general use for minting coins.

There were a number of ways in which the actual coin-striking process itself could be mechanised.

One involved the use of dies with curved faces either striking individual blanks (the rockerpress), or striking

onto strips of metal passed between paired rollers each engraved with several dies (the rotary press). From small

hand driven presses, the development passed via falling hammer presses and water driven hammer works to spindle

presses. In the Tirol city of Hall the first horse-powered coin-striking machine was developed and as early as

1600, Nicolo Grosso used a spindle press in Florence, with which he punched coin blanks from rolled sheets of

precious metals. This technique is still in use today, albeit with high capacity punching presses which produce

large numbers of blanks with one stroke. The permanent refinement of analysis and measuring techniques, the

accuracy of weight and alloy composition were vastly improved.

The coin press (since 1830)

The start of the Industrial Age (late 18th - early 19th century) brought a plethora of various

minting machinery which culminated when around 1830 Diedrich Uhlhorn, a German mechanic invented the coin press

which bears his name. The "Uhlhorn Presse" or "toggle press" substitutes the pressure from the screw of the screw

press by pressure exerted by a lever and is now exhibited at a museum. Later on, the Thonnelier press, set up in

Paris in 1845, was swiftly driven by steam then by electricity. The principle of the "toggle press" which allows

several hundred circulation coins to be produced per minute lives on in today's modern mechanical mint, although

the pace of modern presses nowadays is extremely quick.